converting Lines

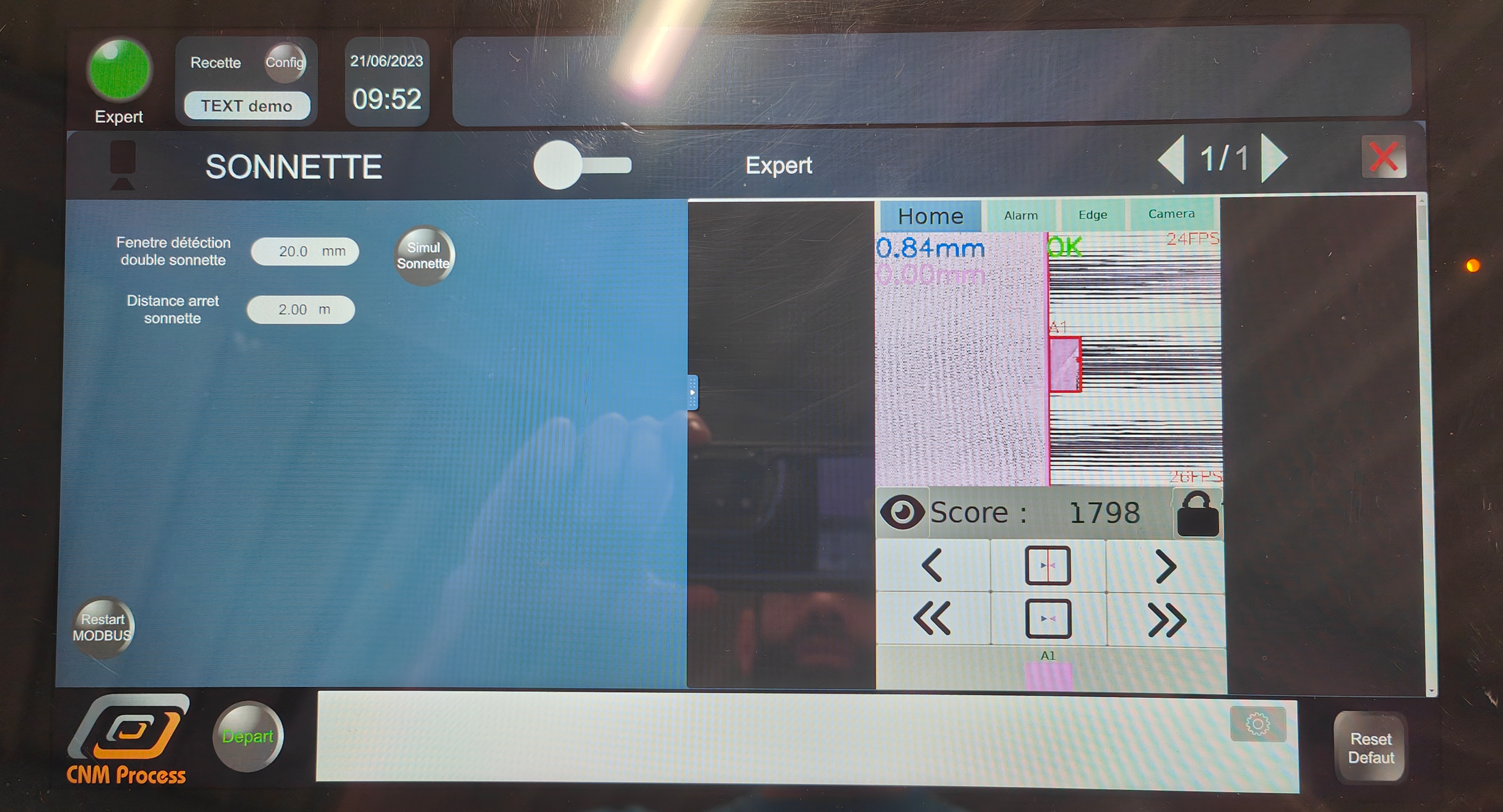

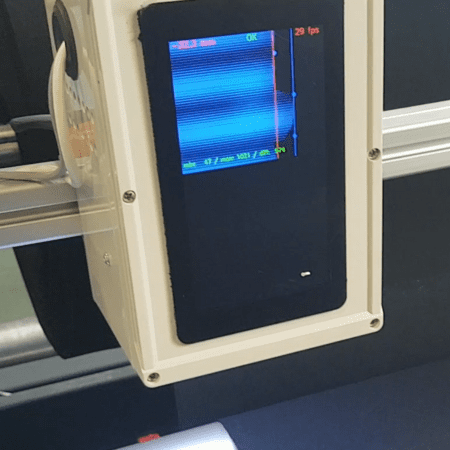

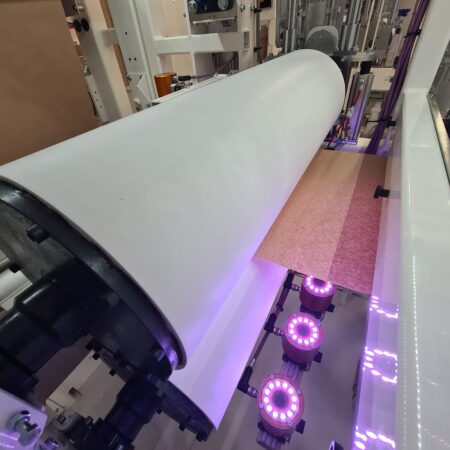

Vision system module

Our vision system is developed internally from A to Z, from the PLC to the camera.

This system offers unequalled precision in process management and line automation.

Several functionalities are available to suit your needs.

Available on all our machines!

Operating modes

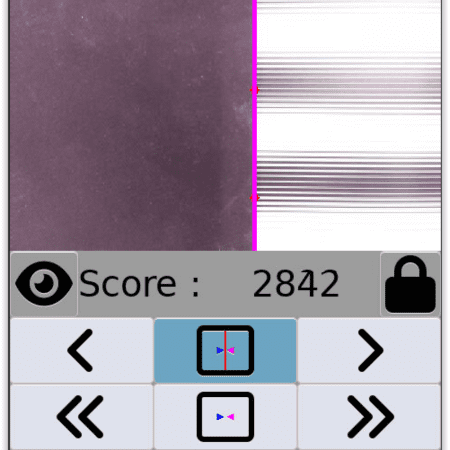

Edges tracker

Our camera is powerful enough to detect an edge through a liner (composites)

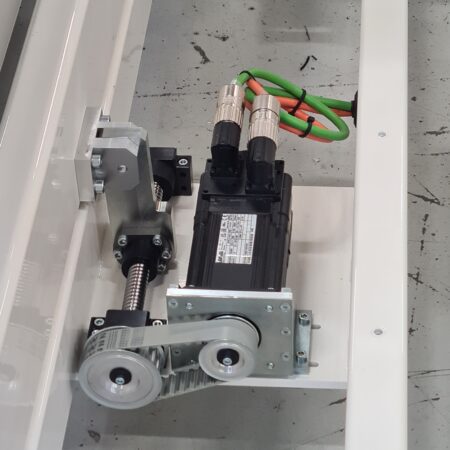

Automatic realignment

Instant re-alignment by moving the unwinding module

Irregular edges

Material edge detection is performed by point averaging, which is very effective on materials with irregular edges (textiles, composites, foams).

Change of references

Thanks to an intuitive system, the origin / reference can be easily modified during the process.

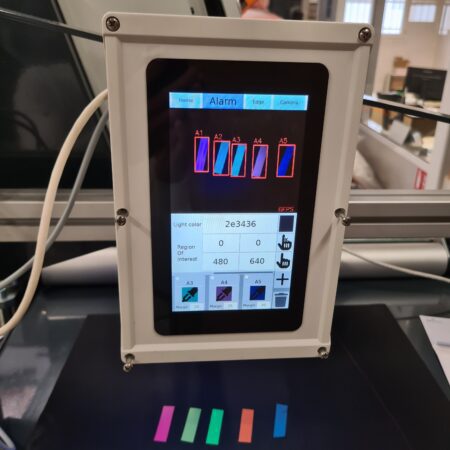

Defect detection

The fault zone is analyzed by the camera, and this information can be relayed to eliminate the fault zone. It is possible to integrate a stop at a precise length for faulty zones without interrupting the cycle.

Labels detection

The PLC designed by CNM Process is capable of detecting different colors and associating directives with each of them (stop, cut, feedback, etc.).