converting Lines

Module: Unwinding - Rewinding

All kind of materials

All rolls types

Proportional valves for friction winding

CNM unwinders are efficient with all types of materials. The unwinder has 3 operating modes selectable by production recipe:

Unwinding with tension control (from 9 N to 250 N): An analog laser sensor sends the position of the puppet (symmetrized by a rack-and-pinion system) to the axis controller. Motor speed is automatically adjusted to keep the puppet at a constant height.

Torque-controlled unwinding with theoretical diameter calculation (from 30 N to 400 N): roll diameter measurement sensor alerts under minimum limit and motor speed clamping.

Tension-free unwinding with material loop (0 N): Distance laser to keep the loop at a constant height regardless of material feed speed.

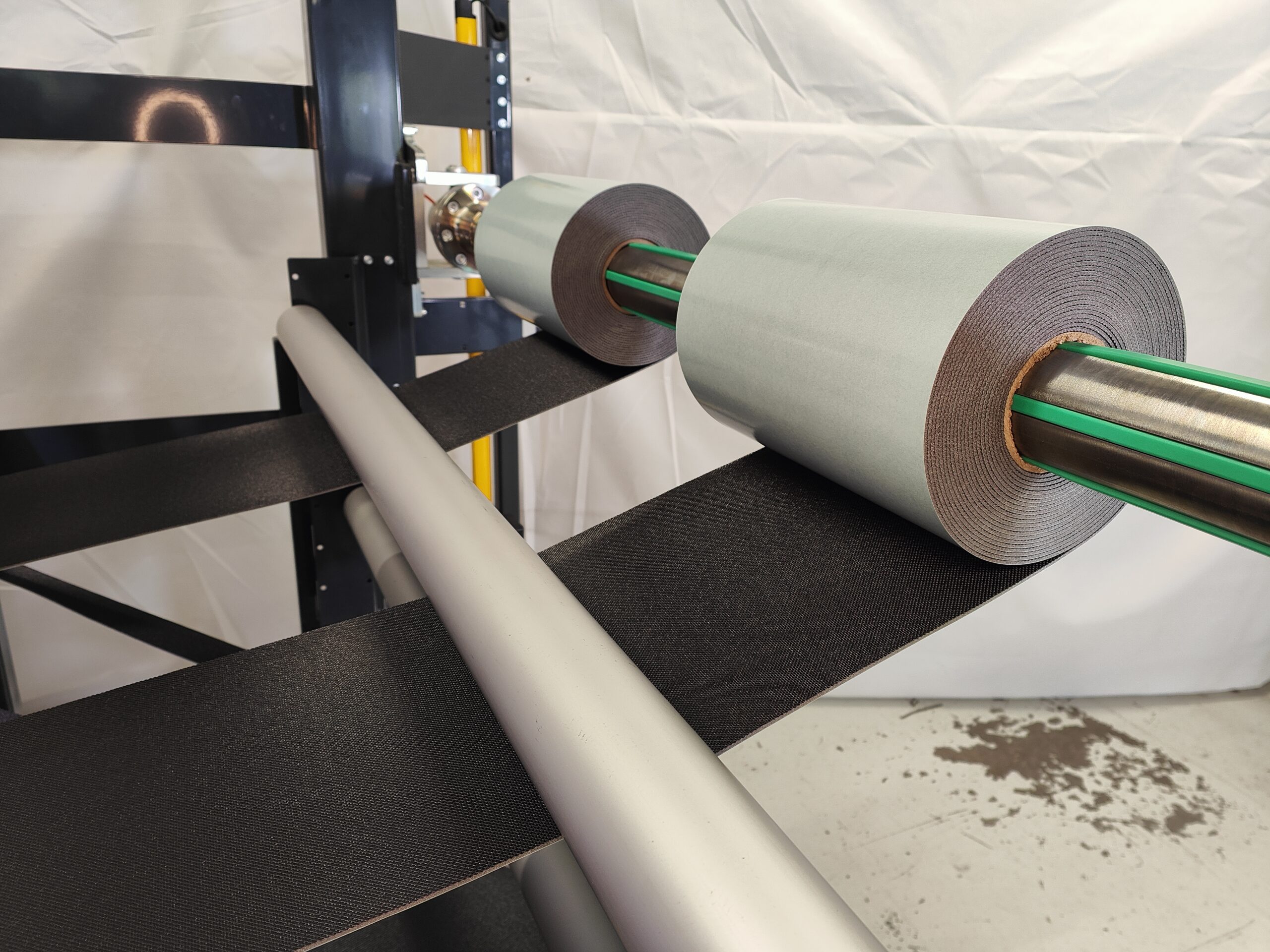

CNM Process unwinders are specially designed to adapt to any type of rolls, thanks to their versatile design and adjustable features.

Friction shafts ensure optimum winding even if the material to be wound is not of the same length or thickness across its entire width. This ensures constant, uniform tension throughout the winding process, helping to prevent problems such as over – or under – tensioning, which can lead to defects in the final roll.