Machine

Unwinder - Rewinder

Reliable, versatile equipment for existing machines

Flexible, versatile equipment to expand your production capacities! CNM unwinders/rewinders are autonomous and designed for integration at the input or output of a production line…

Our models are adaptable to all production machines such as large-format printers, cutting tables, cutting lasers and production lines. Thanks to their design, they can be integrated with all types of material-pulling the materials.

All winders can unwind and rewind, simply by changing the mode on the HMI.

For specific requirements, our design office will develop a customized model to fit perfectly into your process.

Our solutions

Eco Winder M

Ideal solution for textiles

Cost-effective solution

Ideal for textiles

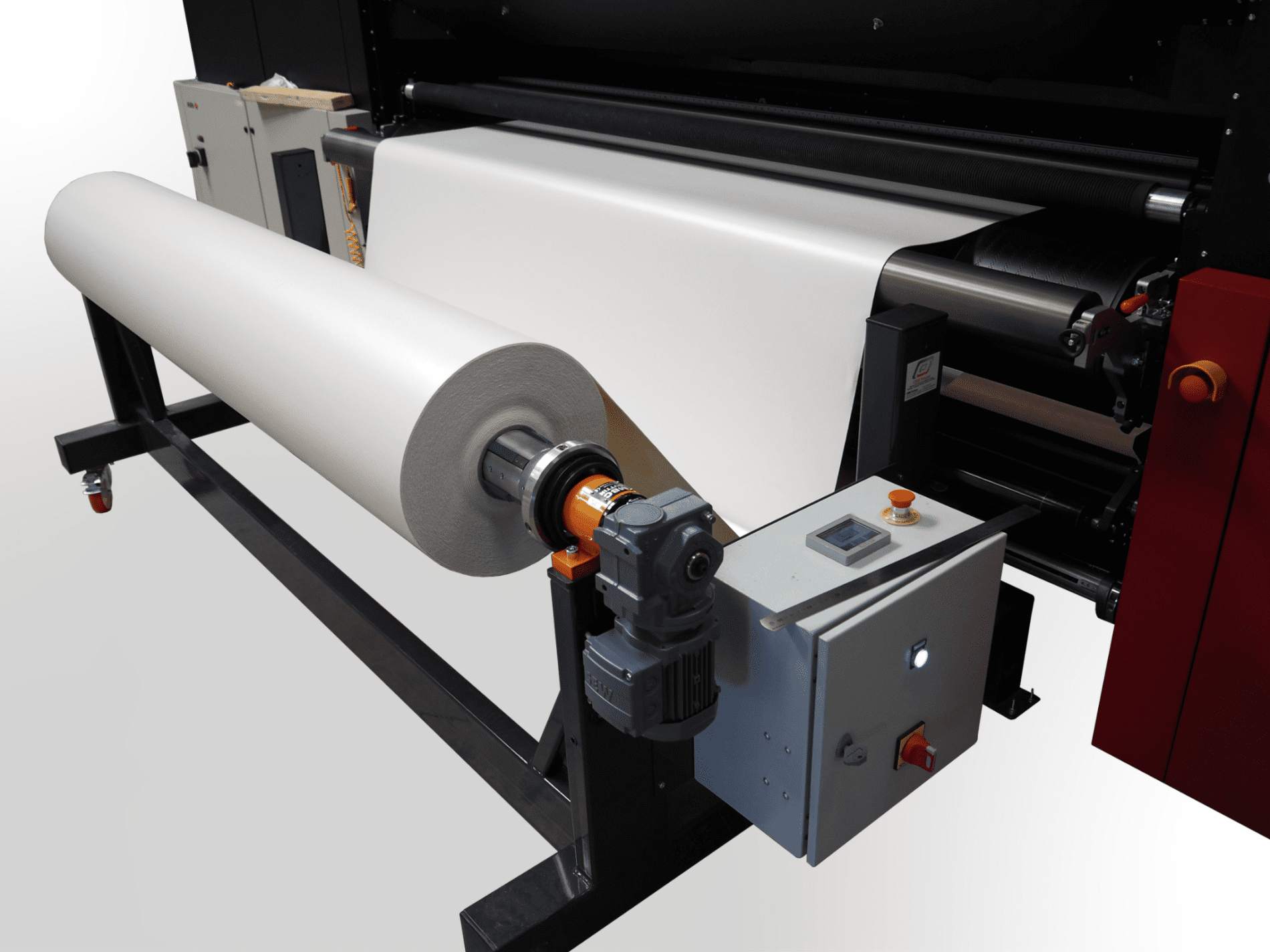

Pro Winder P

A complete, versatile solution

All types of materials

Wide tension range

Smooth and flexible

Advanced work cycle management

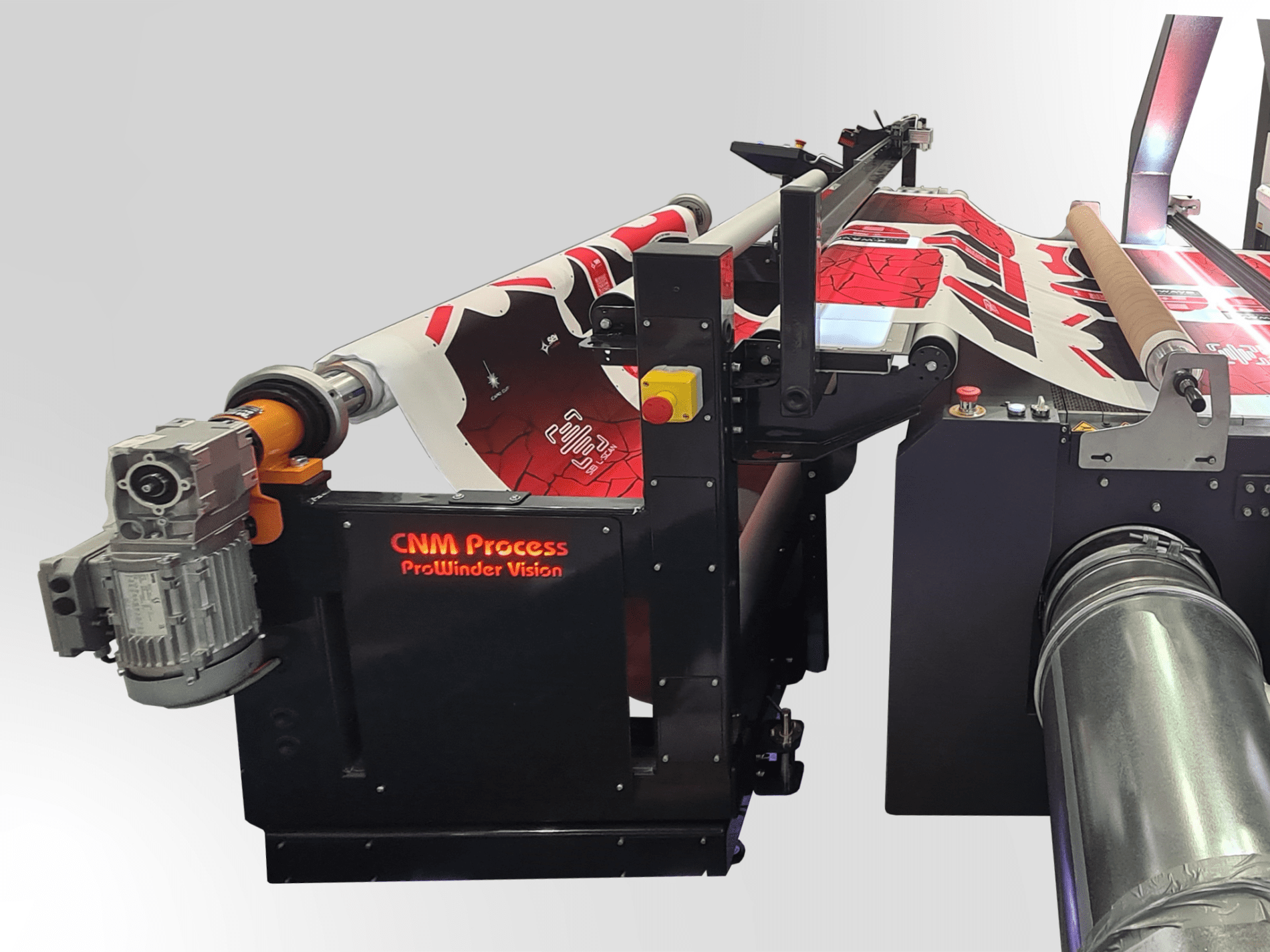

Pro Winder P/V

A versatile solution with vision system

All types of materials

Integrated vision system

Wide tension range

Smooth and flexible

Advanced work cycle management

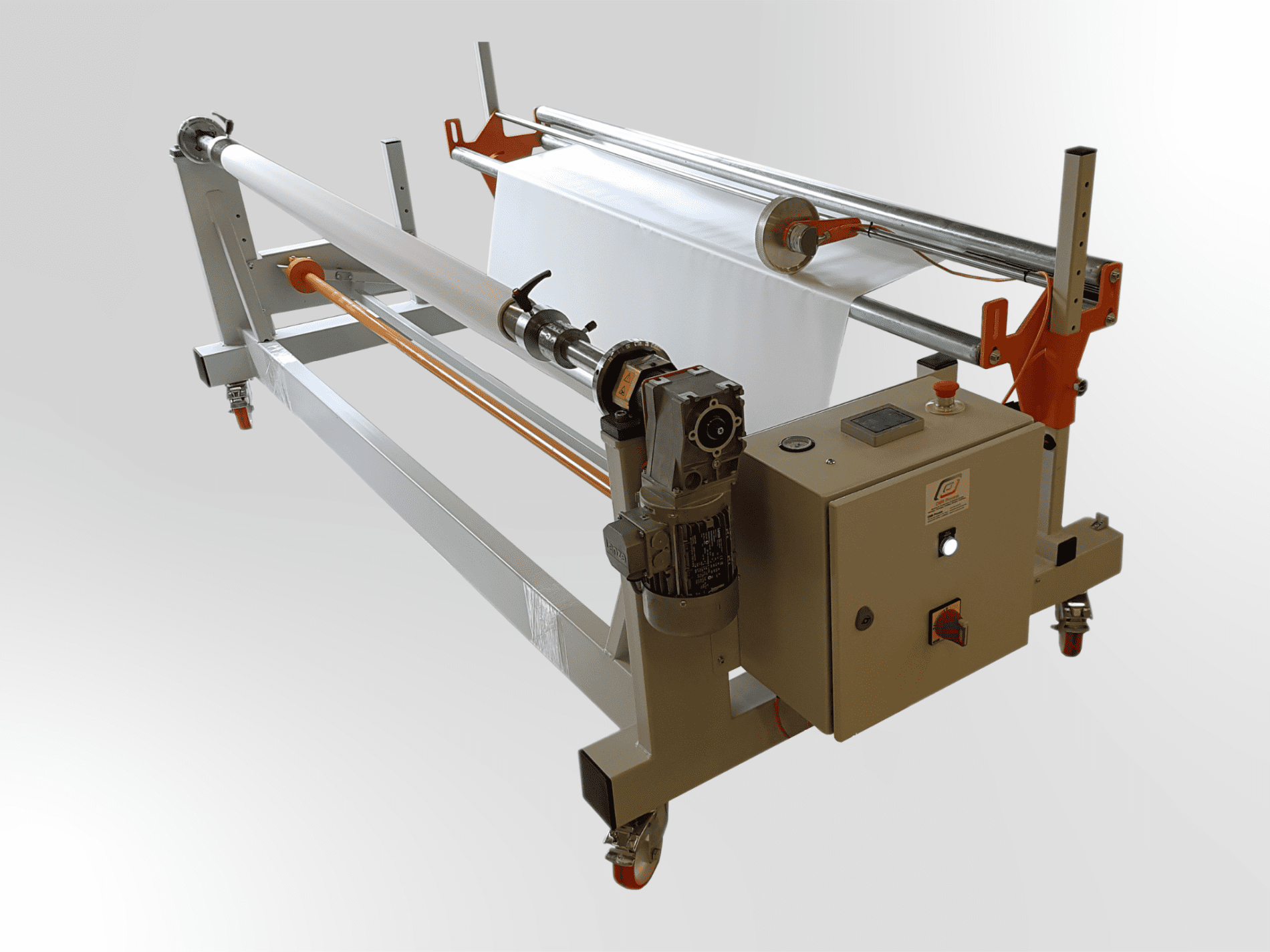

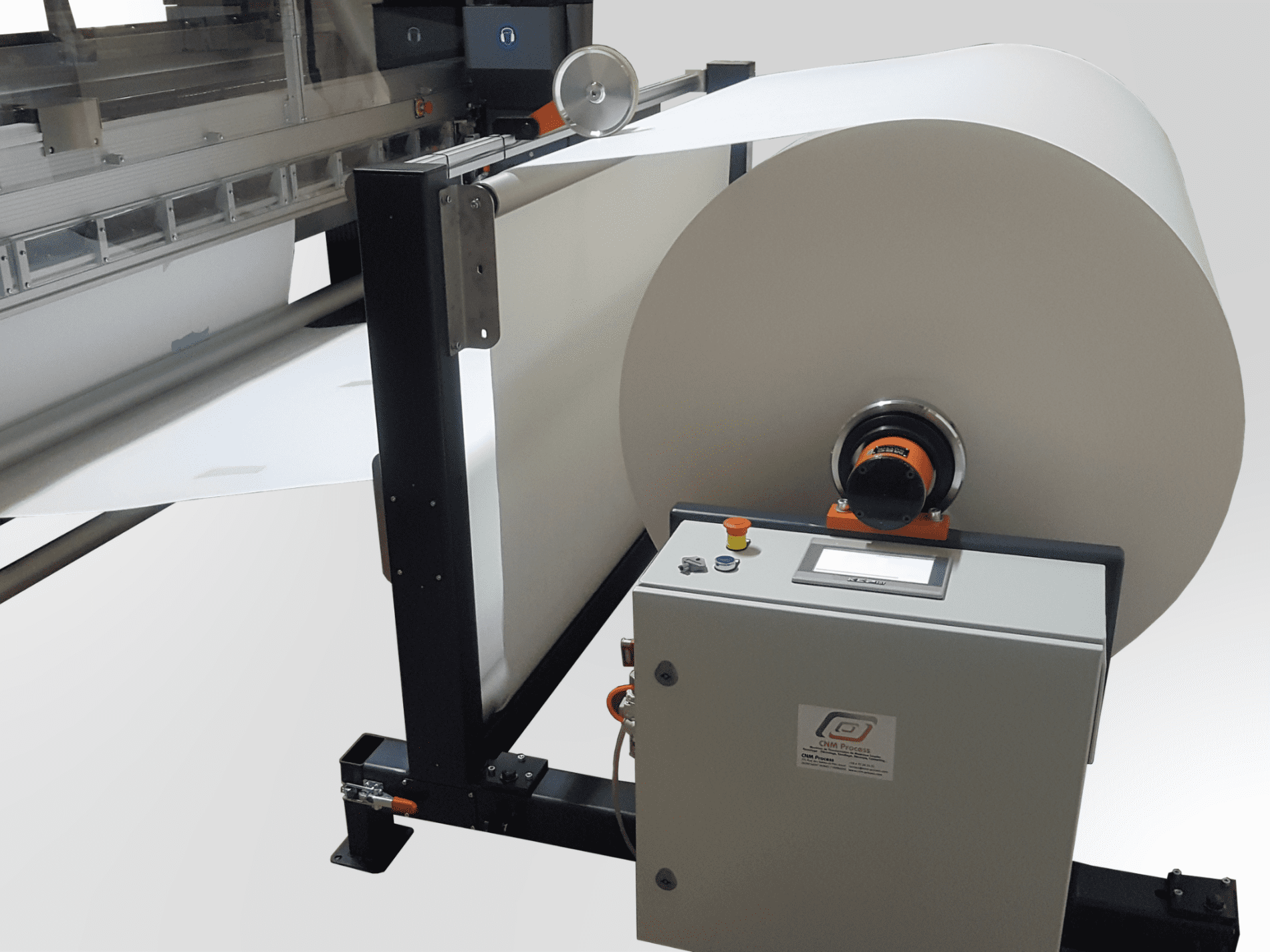

Pro Winder J

Ideal solution for Load & Jumbo rolls

Specially designed for Jumbo rolls

Specially designed for Load rolls

Direct use of factory rolls

All types of materials

Wide tension range

Smooth and flexible

Advanced work cycle management

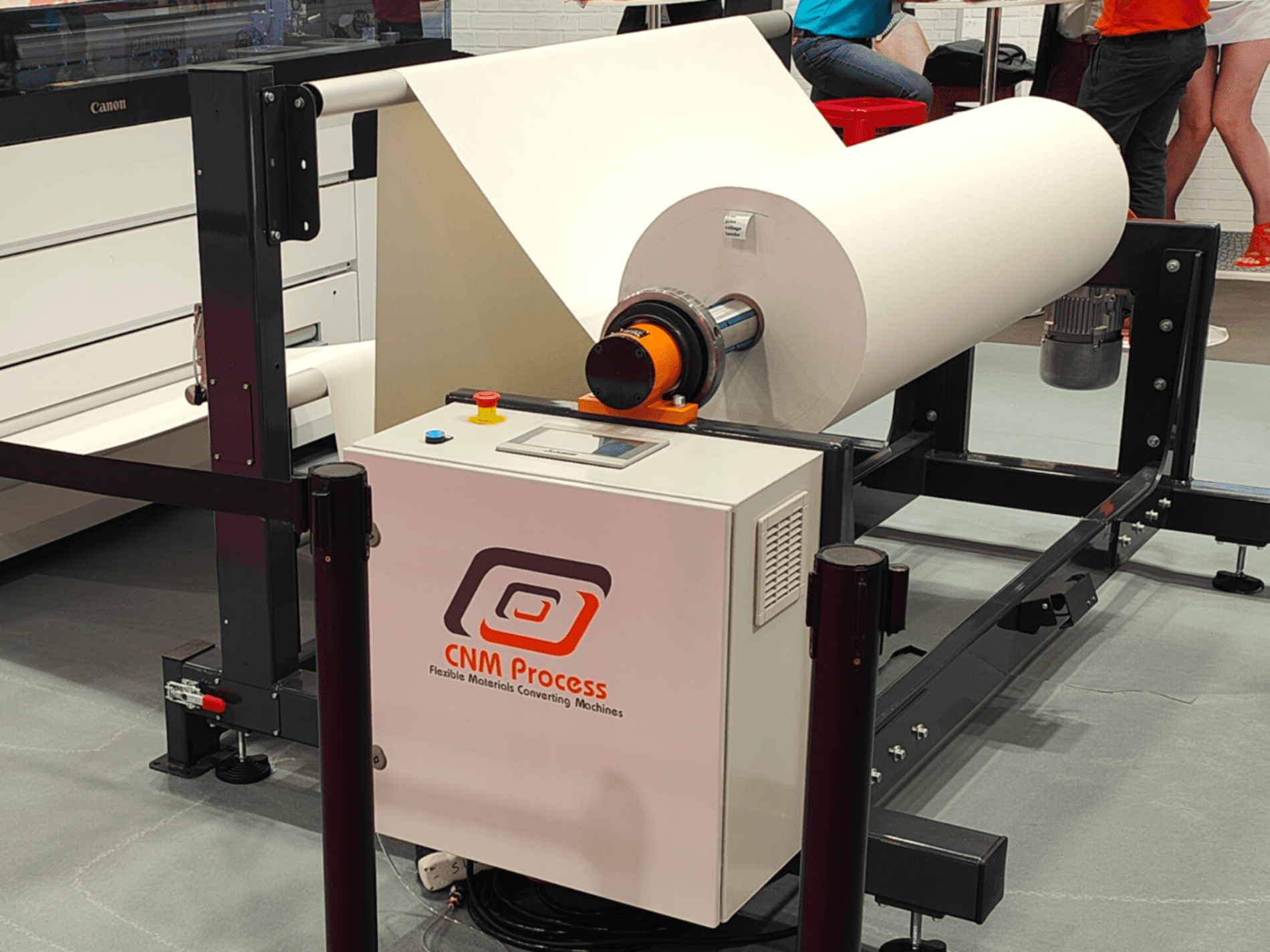

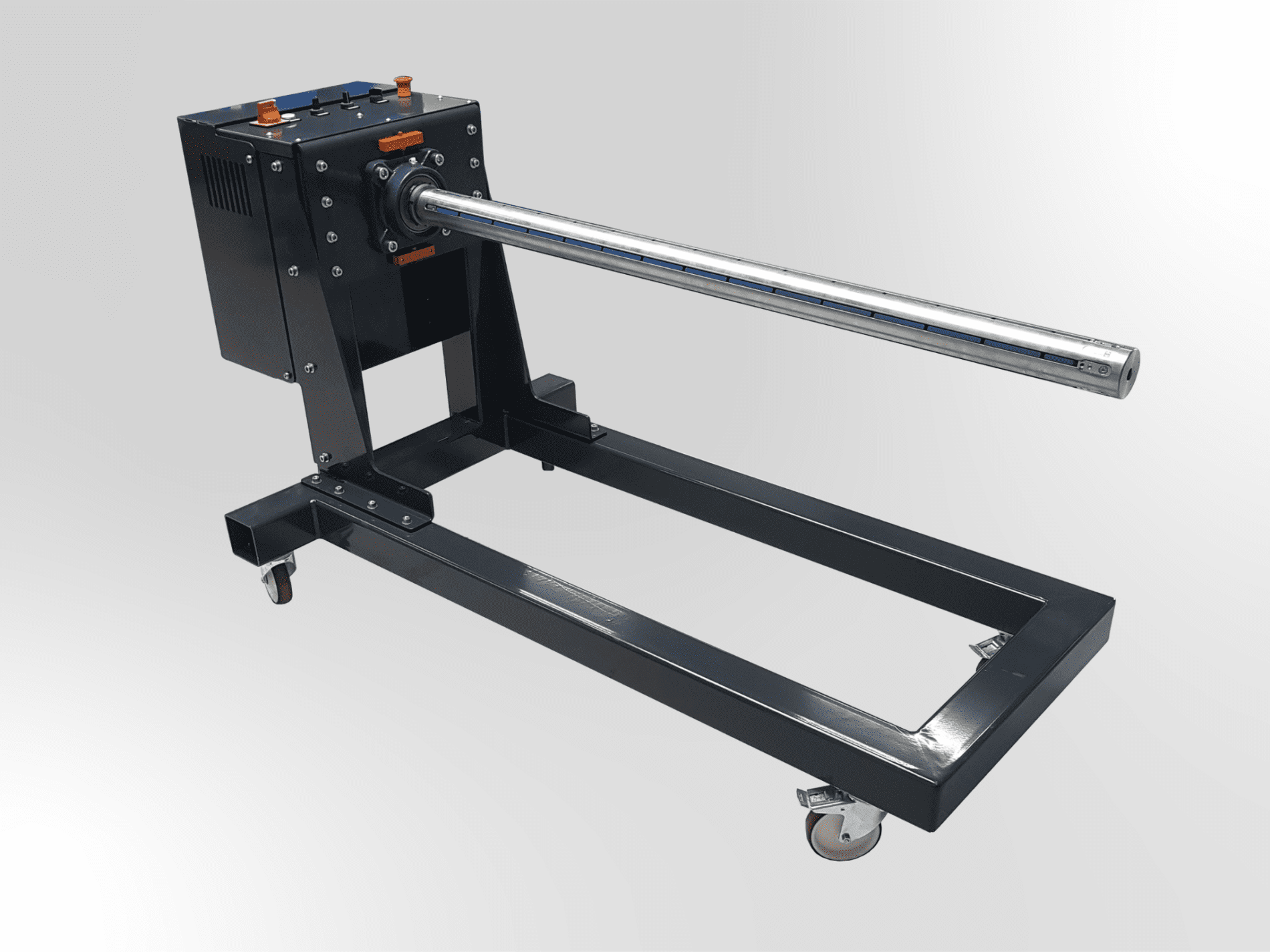

Cantilever winder

Ideal solution for stiff materials

Quick and easy rolls change

Cost-effective solution

Ideal for paper, fabrics and plastic films

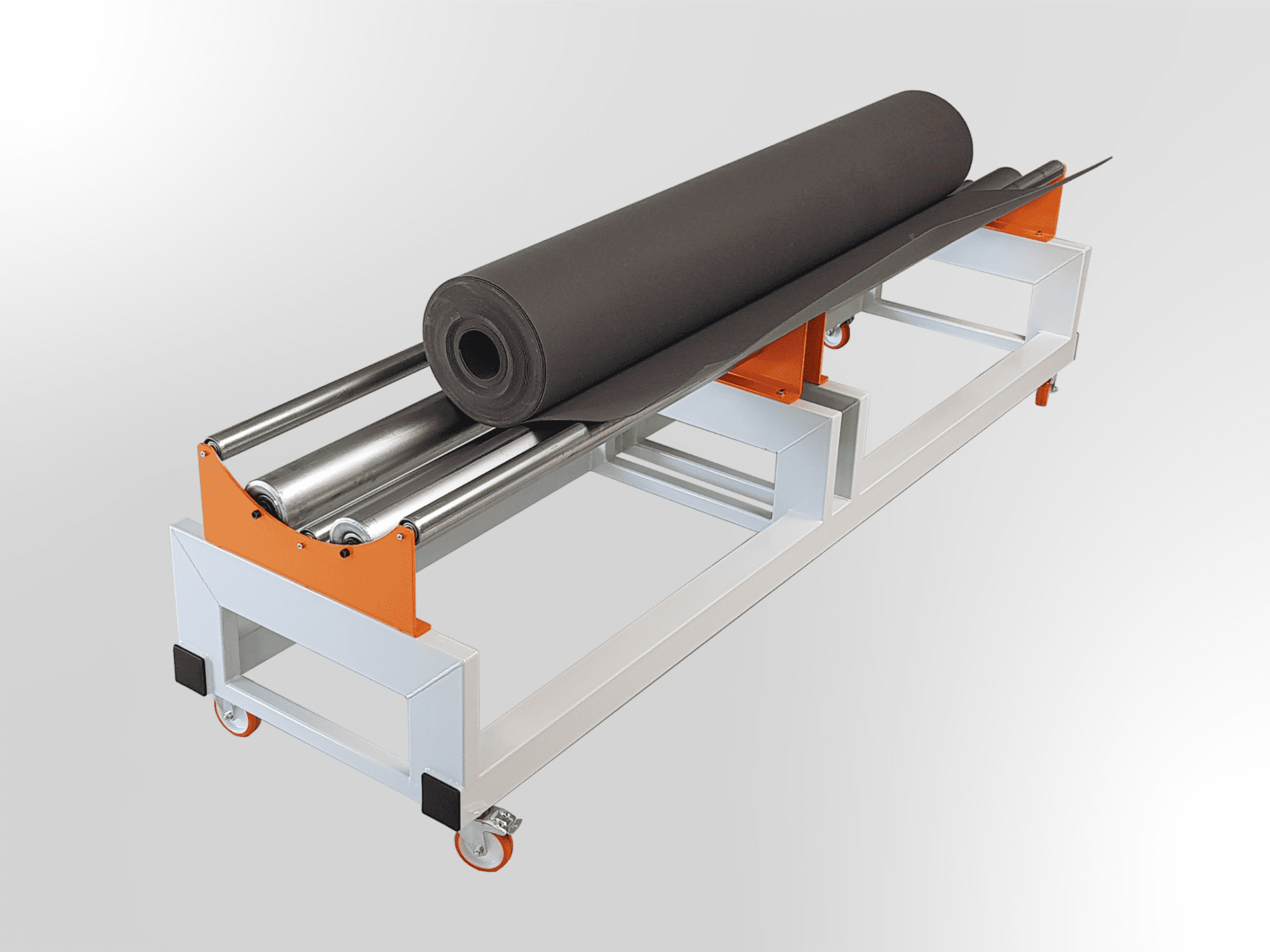

Cradle winder

Ideal for frequent roll changes

Quick and easy rolls change

Coreless unwinding of rolls

Cost-effective solution

Ideal for rough materials

Available options

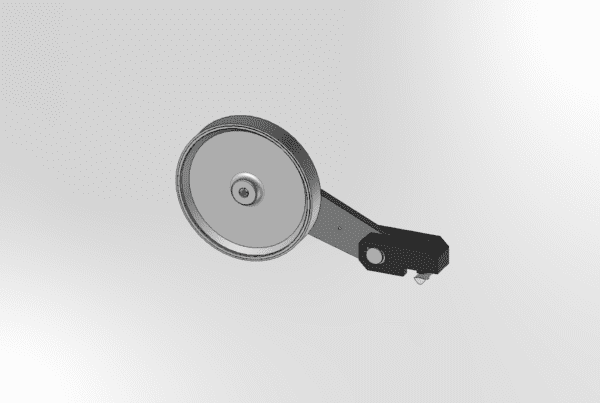

Compteur de mètre

Indispensable solution for printer applications ( reverse detection allows rewinding)

Roll yardage control

Facilitates inventory management and process

HMI feedback (length remaining / unwinded)

Can measure in winding and unwinding mode

A line encoder calculates the unwind length, which can be either in contact with the material or with a detour roll.

Information from the line encoder is displayed on the HMI, with a dedicated space on the home page for entering desired production lengths.

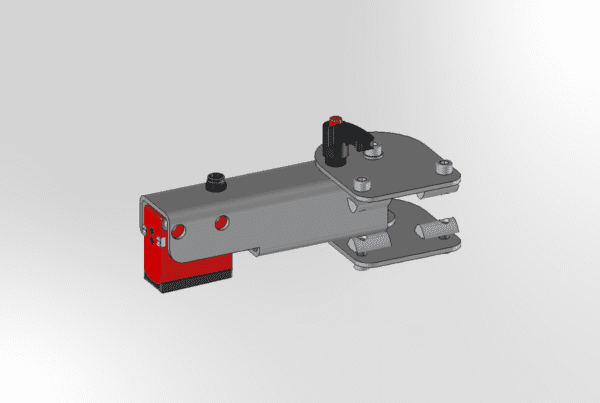

Input Output module

Solution for exchange of information between machines

Start & Stop

Direction (forward / reverse)

Ready

Enables exchange of information between machines: Start and Stop / Direction (forward and backward) /Ready.

Minimum configuration: one input and one output available on the production machine.

Castors + Floor fixings

Useful when the machine is frequently moved

Easy to move and position

Simplified maintenance access

4 PU-coated, braked swivel castors are fitted in place of the machine feet.

An indexing clamp system enables the machine to be quickly secured to the floor.

External sensor in loop mode

Indispensable solution for elastic materials

Ideal for materials such as Lycra, foam rubber…

Allows tension-free unwinding by external equipment

Prevents material retraction after cutting

The material loop passes over the puppet, and a laser distance sensor measures the height of the loop. The motor adapts its speed so as to maintain the loop at a constant height, thus making it possible to follow variations in line speed.

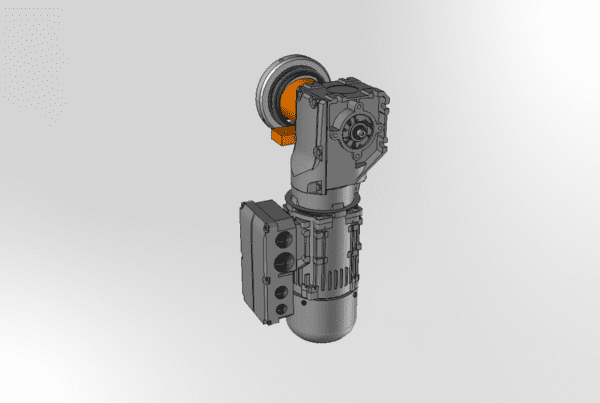

Brake motor

Essential solution for heavy materials

Ideal for materials such as rubber, tarpaulins, carpets…

Prevents unwinding of materials at standstill

Geared motor with service brake mounted directly on a bearing. The brake has 3 operating modes selectable from the HMI (auto / locking / unlocking).