Machine PROLAM

Rubbers converters

Unwinding – Laminating – Cross cutting – Output conveyor

Ideal for rubbers converters

No stress on pieces at the end of the line

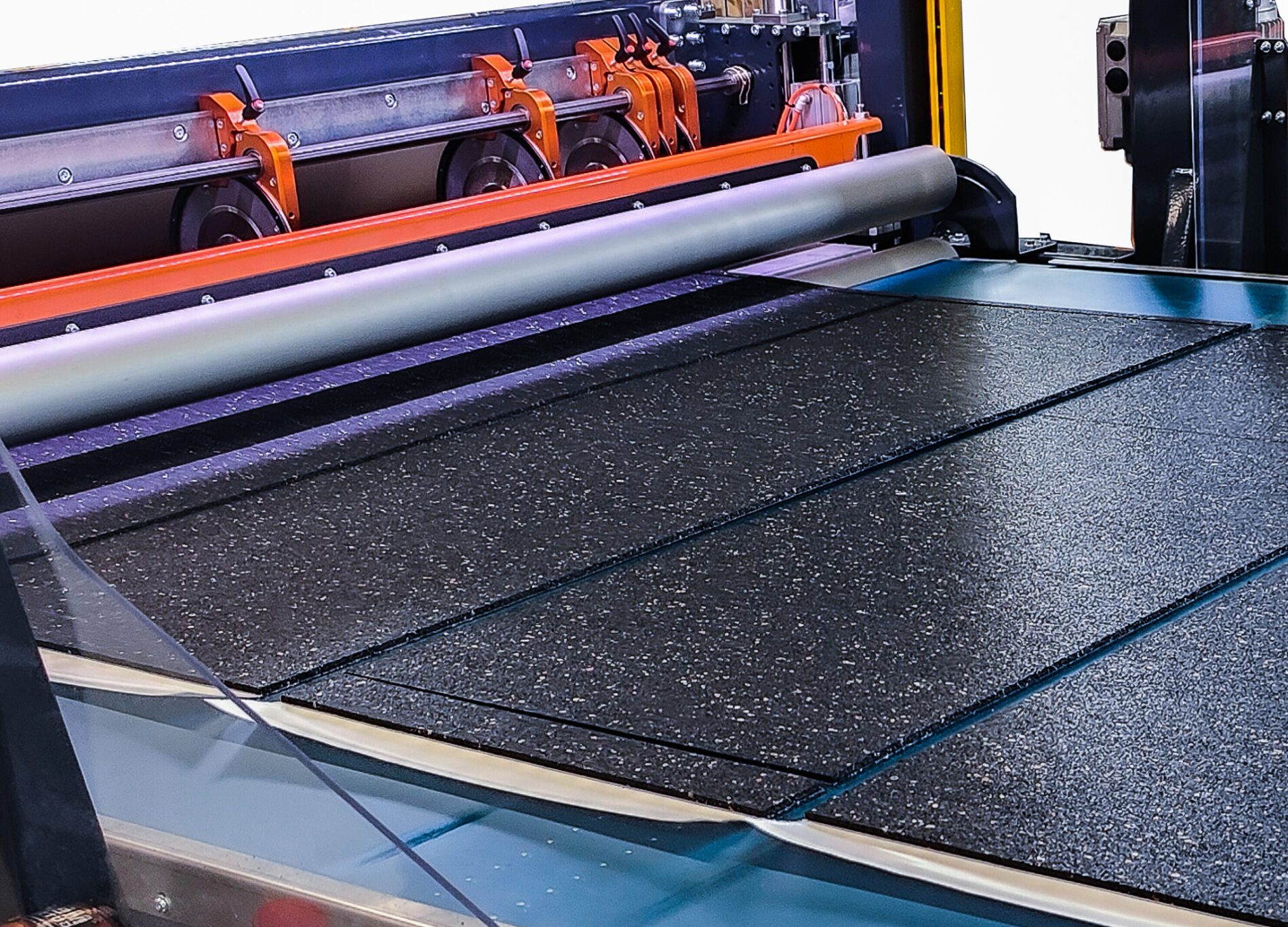

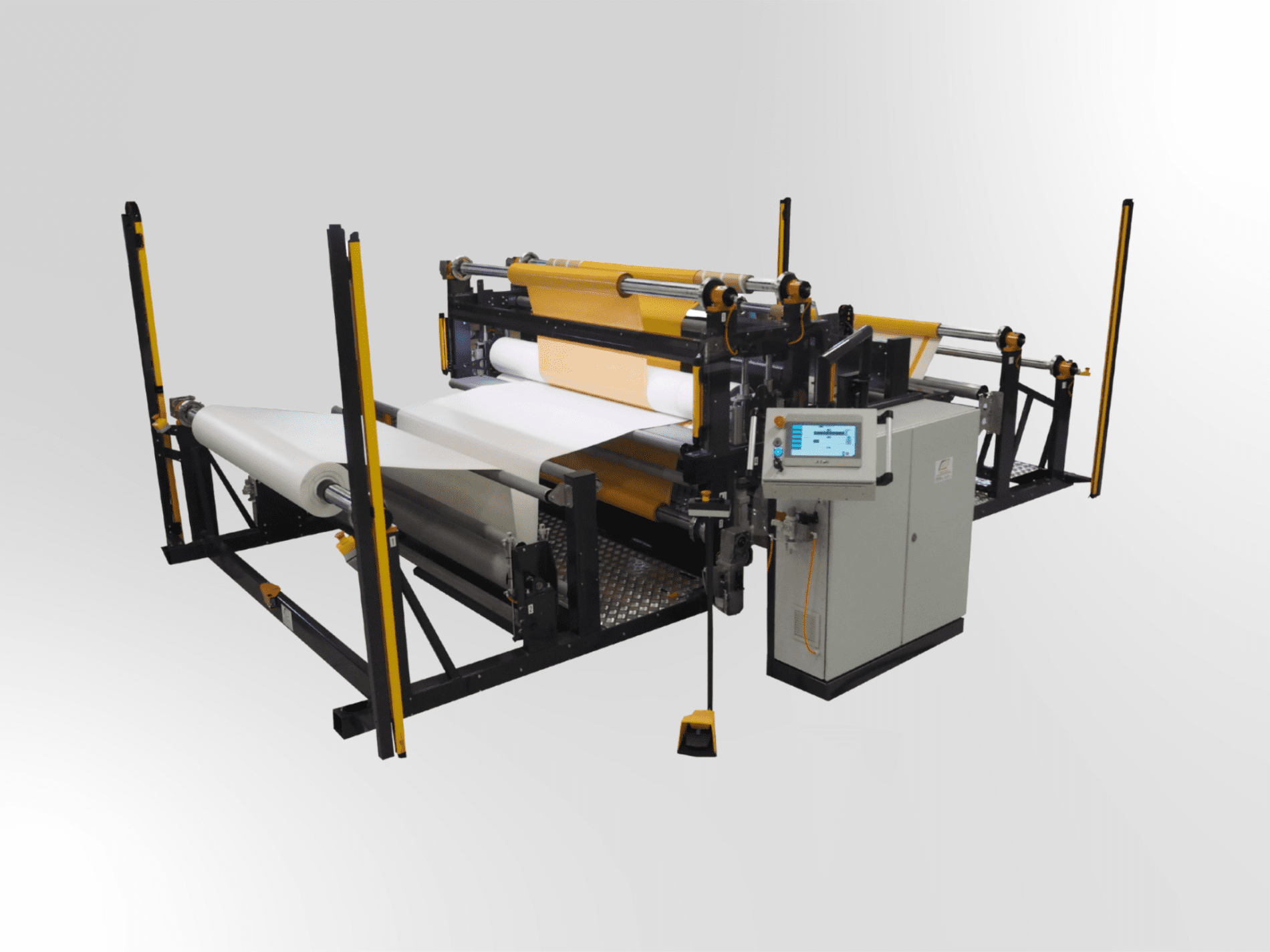

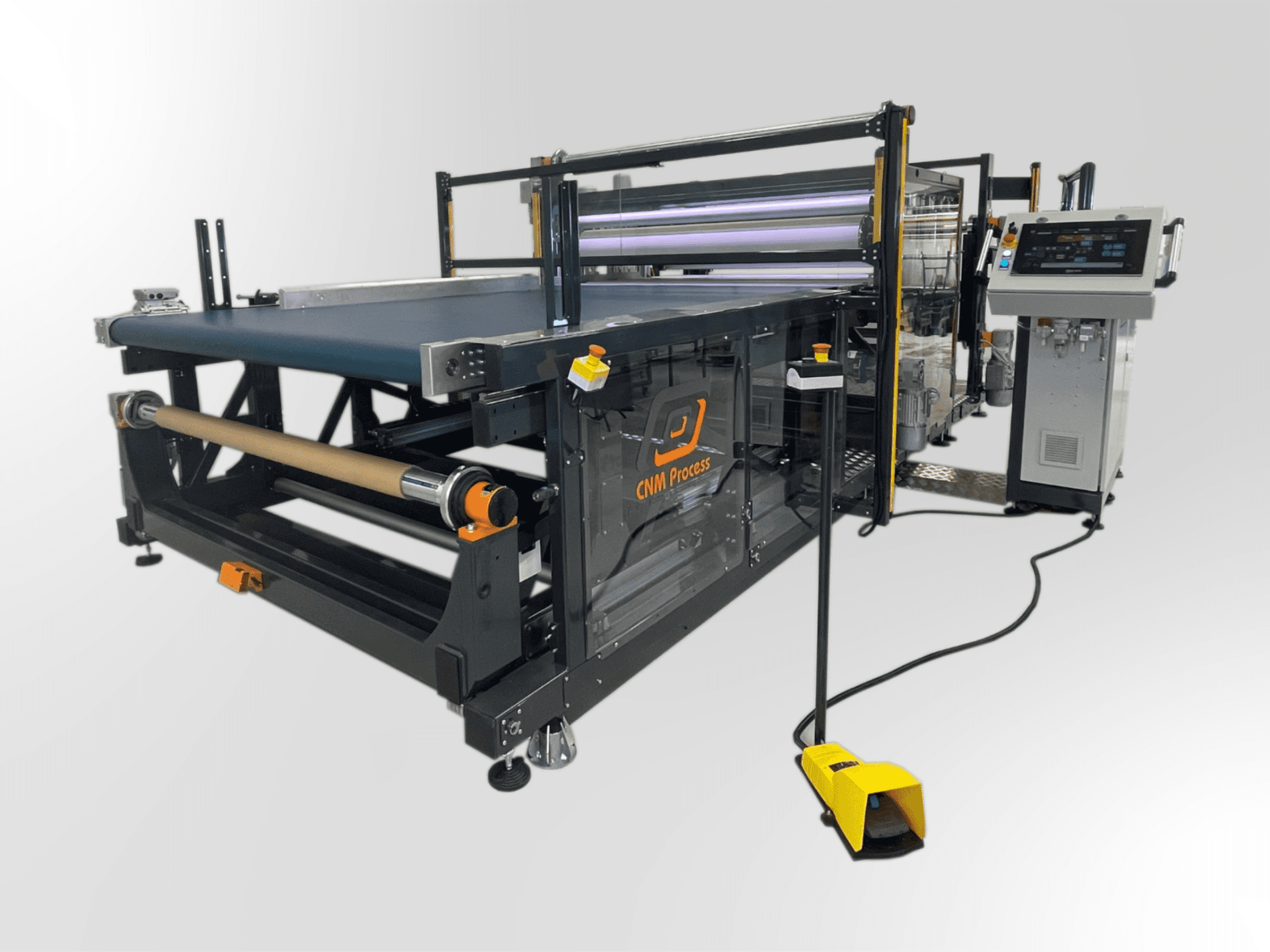

This line offers a complete, automated solution for the efficient processing and transformation of rubber materials. The machine configuration includes several key stages, such as unwinding, complexing, cross-cutting and output conveyor.

The first stage of the converting line is unwinding. Thanks to a precise, controlled unwinding system, the rubber sheets or strips are conveyed smoothly and steadily to the next stages of the converting process.

This is followed by the laminating stage, where adhesives or other materials are added by thermobonding.

CNM Process’s converting line is equipped with an automatic format-cutting system, which enables plates to be cut with consistent precision and high productivity.

Finally, an exit conveyor transports the finished products off the line.

An important feature of the CNM Process converting line is that it ensures that the pieces leaving the line are stress-free. This means that finished products do not undergo unwanted deformation or stress during the converting process, thus ensuring part quality.

In short, the rubber converting line offers a complete, automated solution for rubber converters. It includes unwinding, laminating, cross ying. This machine is ideal for obtaining precise dimensions and stress-free parts.

The others configurations

Adhesives converters

Unwinding – Double sides laminating – Liner removal – Slitting – Rewinding

Ideal for adhesives convertes

Application of thin-width adhesives on borders

Transformateurs de mousses

Déroulage / Convoyeur d’entrée – Complexage – Refente – Enroulage / Table de sortie

Idéale pour les transformateurs de mousses

Mise au pas automatique des plaques