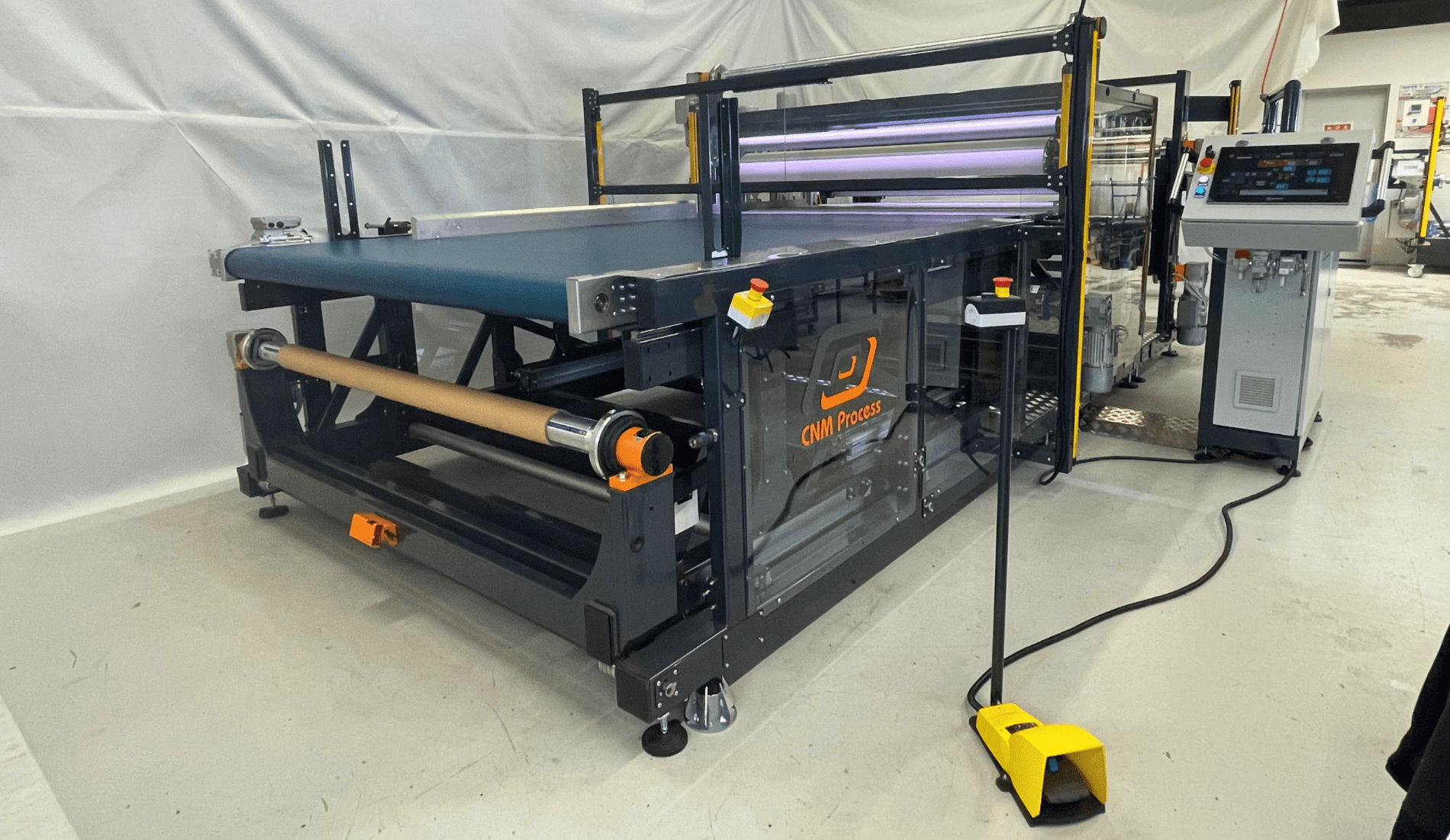

Flexible line for adhesive laminating, and cross-cutting of sheets or rolls

Customer business sector : Automotive & Rail industry

Customer business sector : Automotive & Rail industry

Our customer is a well-known French company specialized in the foams and rubbers converting industry.

Their requirement is for a machine able to laminate double-sided or transfer adhesives onto sheets or rolls. This machine must also be equipped of a slitting and / or a longitudinal cutting system with an output in sheets or rolls.

Several types of material have to be process by the machine, including compact rubber (from 0.5 – 10 mm), cellular rubber (from 1 – 20 mm) and PE and PU foams (from 1 – 50 mm).

The customer’s objectives were to reduce the number of operations, improve lamination quality and dimensional tolerances.

Control production parameters and have a flexible, ergonomic machine suitable for frequent material changes.

In addition, the laminator machine must not generate stresses in the material to ensure the dimensional stability of the cut parts.

First of all, we concentrated on the machine input, the challenge was to be able to work with plates and rolls, while maintaining user ergonomics and excellent process quality.

We therefore integrated a slide-mounted conveyor system, offering excellent ergonomics for operator loading of plates. This device is mobile, allowing easy access to calender, knife settings and inner adhesive loading.

We have included a retractable dancer unwinder in this input module, eliminating the need to store the module outside the machine when not in use. Thus, when the machine is in plate mode, the unwinder is located under the belt. When we switch to roll mode, the material is still driven by the conveyor, which means we can lay out the material well before the lamination step, and also make a material loop to release tension and laminate without stressing the material. For example, for highly sensitive foam rubbers, a loop is created just before the calender input, thus ensuring tension-free operation.

With regard to lamination, the challenge was to avoid warping of the parts after lamination. To achieve this, we doubled our calender module, so that when it passed through the first module, the adhesive came into contact with the foam, holding it in place. During this passage, the opening height is adjusted to the thickness of the material so as not to crush it. Passage through the second “calender” unit enables the adhesive to be definitively fixed to the material. To do this, we have to apply pressure to the adhesive, but since the foam is already held by the adhesive, there’s no warping at the calender output.

For the cutting stage, CNM has developed a solution using motorized circular blades to cut thick foams. This cutting solution enables clean, precise cutting to a maximum thickness of 45 mm.

At the output, a retractable recovery table is provided for sheet recuperation, and two winders slit rolls. Winding is performed on two axes to avoid overlapping of slit rolls during winding.

The customer had three essential materials to be processed on the machine, and this was the basic element of the specification. Thanks to the recipe functions, all that’s needed is to call up a recipe and the machine automatically configures itself, with rewinder activation/deactivation, mode changeover (plate or roll),automatic calender and tension adjustment, enabling all the settings required for the production of a material to be carried out in a single action.

Our customer’s feedback has been extremely positive, highlighting the machine’s precision, stability of settings and versatility in processing different materials.