Machine PROLAM

Adhesives converters

Unwinding – Double sides laminating – Liner removal – Slitting – Rewinding

Ideal for adhesives converters

Application of thin-width adhesives on edges

The machine configuration includes several process step, such as unwinding, double-sided laminating, liner removal, slitting and rewinding.

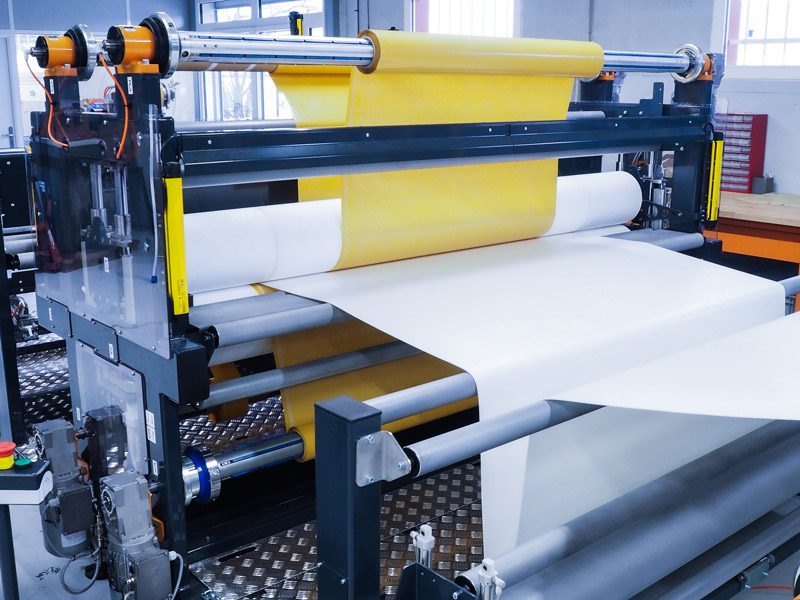

Thanks to a precise, controlled unwinding system, adhesives are fed evenly and stably to the laminating section.

During the laminating stage, adhesive is applied to both sides of a support via a calender. Two unwinders, one at the top and one at the bottom, unwind the rolls of adhesive under tension control, while a rewinder removes a liner at the calender exit.

Slitting is used to cut adhesives into strips or specific dimensions, adapted to customer requirements. This step is essential to obtain finished products with precise dimensions and to meet the requirements of different types of application. If necessary, another winder allow to rewind the remaining skeleton.

Finally, the rewinding section guarantees controlled and precise winding of the finished products, ensuring consistent quality and ease of use for customers.

Thin-width adhesives can also be applied during the process.

The others configurations

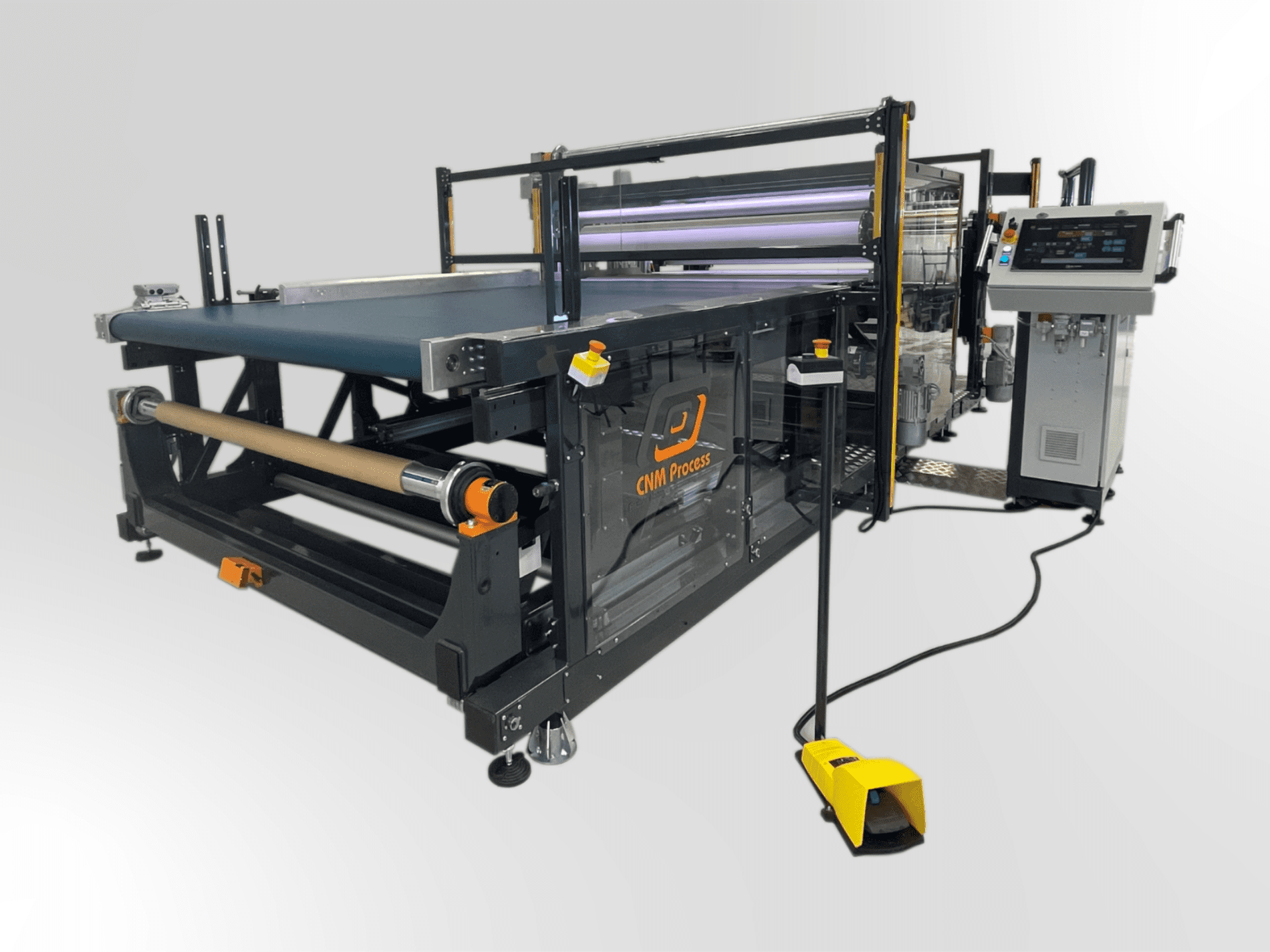

Foams converters

Unwinding /Input conveyor – Laminating – Slitting – Rewinding / Output talble

Ideal for foams converters

Automatic plate stepping

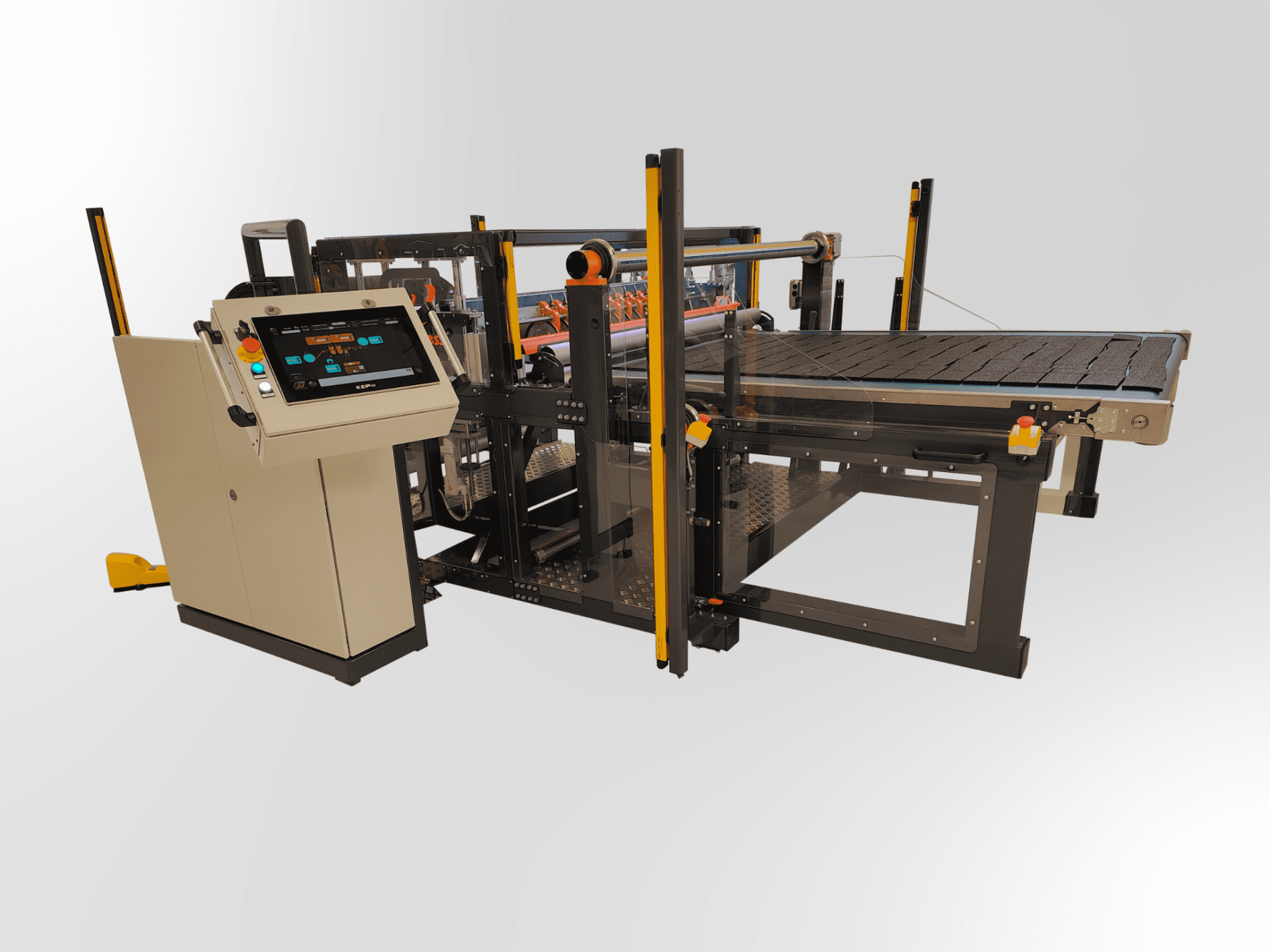

Rubbers converters

Unwinder – Laminating – Cross cutting – Output conveyor

Ideal for rubber converters

No stress on pieces at line exit